Embodied Carbon and Glass

As architects and glaziers work to design and construct building projects in a more sustainable manner, the consideration of embodied carbon has become a bigger factor in understanding the overall impact of a project’s carbon footprint.

Designers are working to balance the reduction of emissions from a building’s operations, known as operational carbon, with emissions caused by the manufacturing and installation of construction materials, known as embodied carbon.

Evaluating Embodied Carbon

In 2017, Vitro became the first North American manufacturer to publish third-party verified Environmental Product Declarations (EPDs) for flat glass and processed glass products. These documents provide detailed data about the life cycle impacts of Vitro glass products on the environment. EPDs may be used as credentialing for LEED® and other green building certification programs and are now necessary to demonstrate compliance with embodied carbon limits in places like California, which recently amended its CALGreen Building Standards Code to place limits on embodied carbon emissions in commercial and school buildings.

In 2019, the National Glass Association (NGA) published an architectural glass EPD that evaluated the embodied carbon of clear, low-iron and tinted flat glass produced by four member companies of the NGA’s Forming Committee, including Vitro. Its findings suggested an industry average GWP of 1,430 kilograms for comparable products.

Vitro recently announced it received an updated Environmental Product Declaration for its flat glass products that indicate its architectural glass products contain just 1,240 kilograms of CO2 equivalent, which is 13% lower than the National Glass Association’s industry standard.

Low Embodied Carbon (LEC) Standards

In 2024, the General Services Administration (GSA) announced that it has set standards for products that can be considered low embodied carbon (LEC). As part of achieving these standards, products must offer a Type III EPD with a GWP in kilograms of carbon equivalent per metric ton (kgCO2 eq/ton) of glass.

Based on our latest EPD results, all Vitro Architectural Glass products meet the Top 20% ("Most Preferred") LEC material category. This lowest embodied carbon designation applies to all Vitro-produced architectural glass from all Vitro plants all the time.

Glass is one of four building products for which the GSA has leveled LEC standards, and while other types of products may need to sacrifice quality to achieve LEC status, Vitro has employed carbon reduction measures that improve energy efficiency in the glass production process without altering the composition, characteristics, clarity and strength of our glass products.

Every effort made to reduce embodied carbon adds up and can create a significant impact. For example, if a building has 30,000 square feet of dual-glazed IGUs, it contains 90,000 tons of glass weight. With Vitro’s third party certified GWP of 1350, the building would contain 121.5 tons of embodied carbon equivalent from the glass. However, a different glass product with just 100 additional CO2 eq of GWP would result in the building containing 130.5 tons of embodied carbon equivalent. For reference, the EPA estimates that a typical passenger vehicle emits 5.1 tons of CO2 per year, so selecting a glass product from Vitro with lower embodied carbon would be equivalent to removing about 3,500 cars from the road – or 3,529 to be exact.

To learn more about embodied carbon and the relationship between carbon and architectural glass production, please see “What is Embodied Carbon?” on Vitro’s Glass Education Center website

Understanding EPDs

It is important to understand how to properly read, interpret and utilize data that is published in EPDs, which should generally be used to inform and indicate compliance with the requirements of green building rating systems and legislative actions. The purpose of an EPD is to provide information on the environmental impact of the product over the life cycle, and they typically rely on estimations of impacts and can therefore differ across product lines and reported impact.

It is especially important to verify when interpreting EPDs whether the document applies only to a specific product or all products of that type. Unlike some other manufacturers, Vitro’s EPDs are product-specific, meaning that the information included applies to all Vitro’s North American-made flat and processed glass products manufactured at any Vitro glass plant, and is not limited to one specific product type or location.

In the context of evaluating embodied carbon, EPDs will likely offer the most value in interpreting how a given product was manufactured and what steps manufacturers are taking to reduce energy expenditures. For more information, review the National Glass Association’s General EPD Education document and the “Understanding EPDs” article on Vitro’s Glass Education Center website.

Developing the EC3 Tool

Along with being the first North American glass manufacturer to publish third-party verified EPDs, Vitro Glass is participating in the development of the EC3 tool for architectural glass. Envisioned by the non-profit Building Transparency, this calculator is being created to help architects and other stakeholders benchmark, assess and reduce the amount of embodied carbon used among all the building products (including glass) specified for their construction projects.

Carbon and Architectural Glass Production

Perhaps the most comprehensive metric to consider as it relates to embodied carbon in glass (or any building product) is Global Warming Potential (GWP). This measure takes all the energy used to create a product and converts it into kilograms of equivalent carbon dioxide, expressed as the term “CO2-eq.” The purpose of calculating GWP is to help stakeholders and sustainability programs more effectively gauge the environmental performance of glass and other products manufactured for buildings.

Most of the embodied carbon in glass originates with the energy-intensive process of heating the melting furnace to 3,000 degrees Fahrenheit to convert a blend of silica, soda ash, dolomite, metal compounds and recycled cullet glass to flat glass.

The processes of adding energy-efficient low-e coatings, tempering, laminating and fabricating flat glass into insulating glass units also contribute to the glass’s GWP – but to a lesser degree.

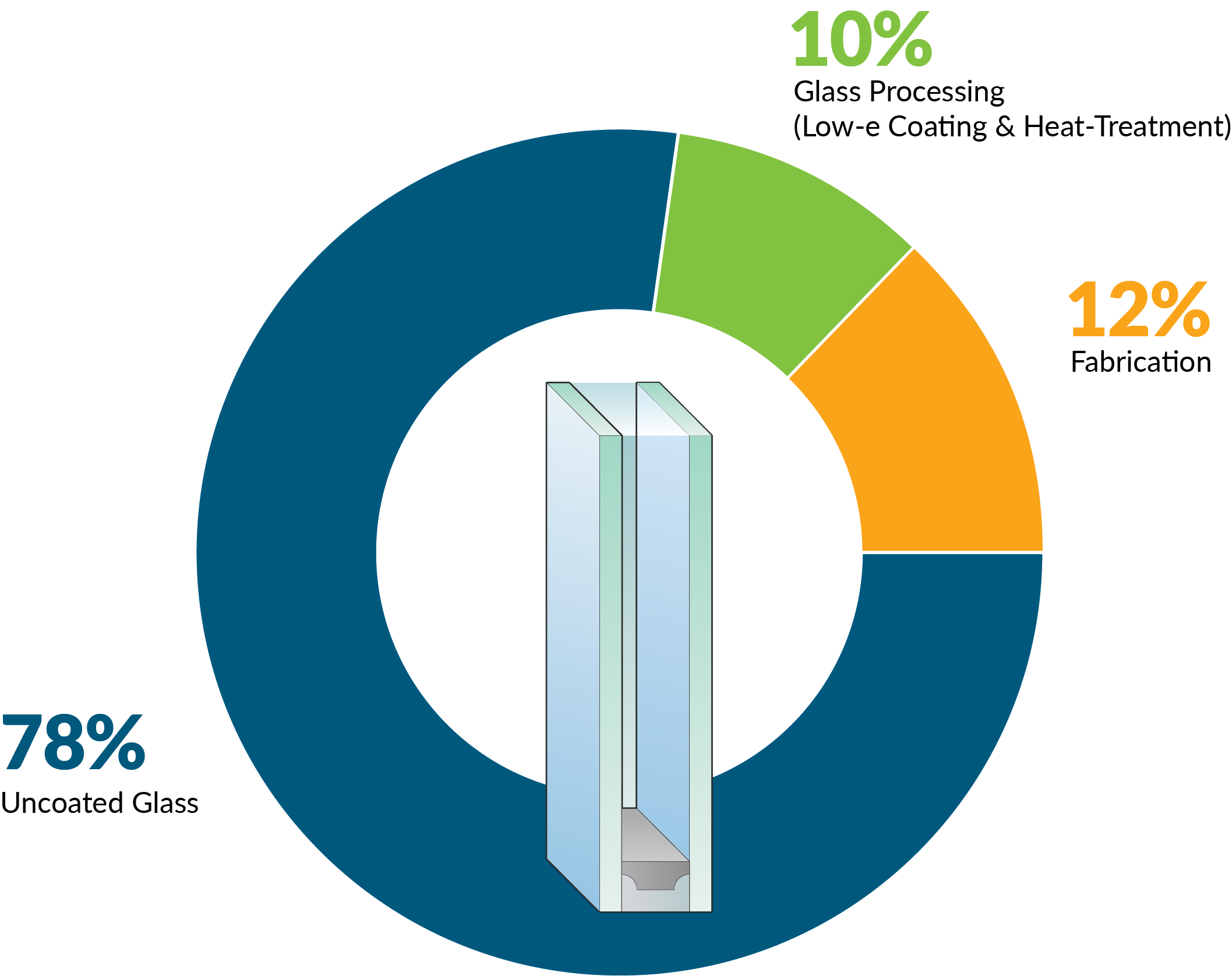

In fact, approximately 78% of the embodied carbon in an insulating glass unit (IGU) can be credited to the manufacturing of flat glass lites. It is estimated that of an IGU’s remaining embodied carbon, 12% comes from the IGU fabrication process itself and just 10% comes from the process of adding low-e coatings and heat treatment processes.

Reducing Embodied Carbon

To further reduce embodied carbon in architectural IGUs, Vitro is taking the following steps to reduce overall energy consumption in glass production:

- Developing expertise in furnace control systems to reduce variability of melting temperatures and fuel consumption

- Adding new low-NOx burners in our plants

- Using variable frequency drives on cooling fans to reduce energy use

- Utilizing recycled cullet (both pre- and post-industrial) to reduce fuel consumption

- Converting all facility lighting to LED, which reduces electric consumption by as much as 80% vs. incandescent lighting

- Using oxy-fuel technology at three plant locations in the U.S., which can reduce energy consumption in glass melting furnaces by as much as 20% and cut greenhouse gas emissions in half

It also is important to note the return on carbon that energy-efficient glazings deliver. While the production of raw glass does carry embodied carbon, high-performing low-e coated glass reduces the negative environmental impact of the built environment. Between reducing solar heat gain and providing daylighting, modern architectural glass reduces carbon emissions for thousands of homes and buildings each and every year of their very long lifespan.