VacuMax™ Vacuum Insulating Glass (VIG) by Vitro – Turning Walls into Windows

VacuMax™ vacuum insulating glass (VIG) by Vitro Architectural Glass integrates with any traditional (and even non-traditional) glazing system to maximize insulation performance. With wall-like R-values up to R20, VacuMax™ VIG is the ultimate in thermal glazing.

The newest generation of VacuMax™ VIG is now manufactured exclusively with Solarban® 70 solar-control, low-e glass by Vitro and can be used alone as nominal ¼” glass to replace monolithic (single-pane) glass without needing to replace the framing system. Additionally, a new manufacturing process means the next generation of VacuMax™ VIG units don’t require a vacuum port and feature a getter that’s hidden from view.

What is Vacuum Insulating Glass (VIG)?Back to Top

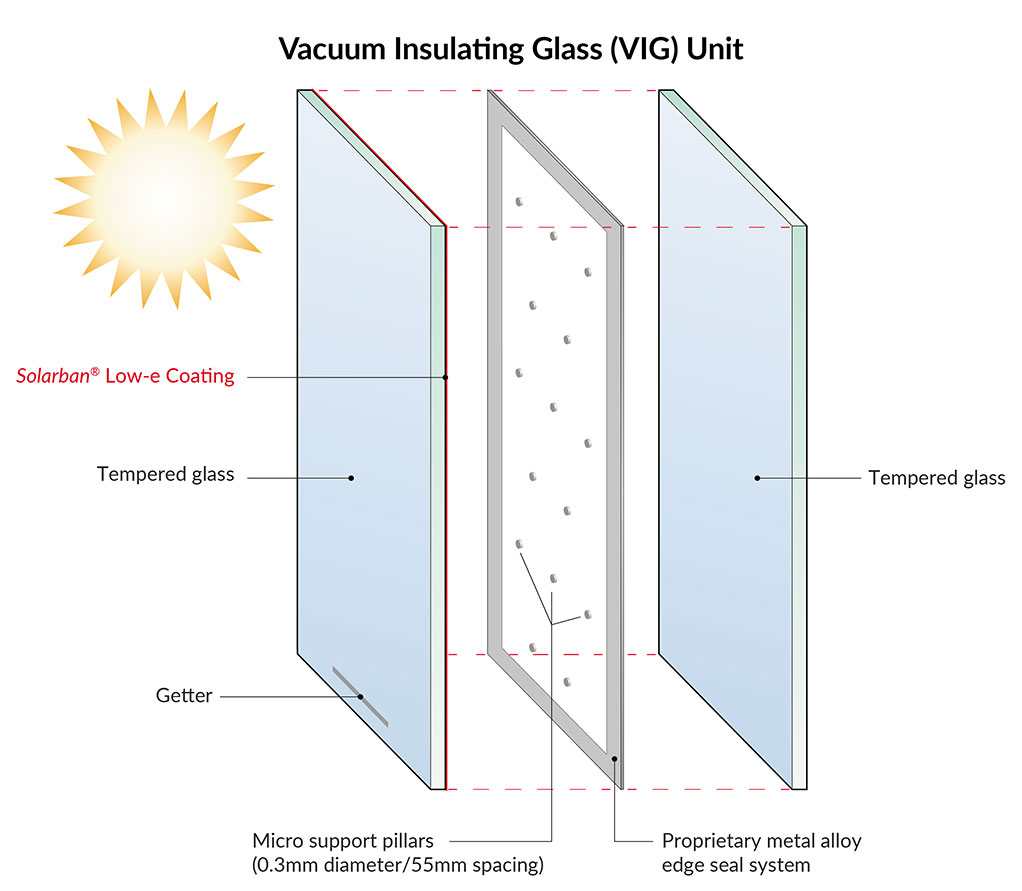

A VacuMax™ VIG unit consists of two lites of glass, ranging from 4mm to 6mm, separated by a non-leaded proprietary metal edge seal and a vacuum space. The unit’s slim construction and light weight allows it to be incorporated into virtually any traditional glazing system, window frame or curtainwall application.

VacuMax™ VIG Unit Dimensions:

- Available with a minimum thickness of 8.3 mm (with 4mm lites) and a maximum of 12.3 mm (with 6mm lites).

- Available in sizes from 12”x12” (0.3m x 0.3m) to 60”x118” (1.5m x 3.0m). Contact your Vitro architectural representative for more details.

VacuMax™ VIG dons the newly renovated Hugel Welcome Center in Markle Hall on the campus of Lafayette College in Easton, PA, the first project in the U.S. to feature VacuMax™ VIG by Vitro Architectural Glass. (Photography: Jim Cunningham)

Performance Benefits

VacuMax™ VIG units enhance the performance of any glass configuration by effectively blocking thermal transmission, delivering thermal insulation performance that is 3-5x better than conventional insulating glass and up to 20x better than monolithic glass. VacuMax™ VIG also offers extraordinary R-values and delivers energy savings and reduced carbon emissions.

Compare the baseline performance of VacuMax™ VIG units to traditional IGU components and configurations.

| Attribute | Monolithic (Single-Pane) Glass 6mm Clear |

Double-Glazed IGU Solarban® 70 (2) Clear + Clear |

Triple-Glazed IGU Solarban® 70 (2) Clear + Clear |

VacuMax™ VIG Solarban® 70 |

|---|---|---|---|---|

| U-Value (Btu/hr•ft2•˚F) | 1.02 | 0.28 | 0.15 | 0.05 |

| R-Value | 1.00 | 3.60 | 6.66 | 20.00 |

| Visible Light Transmittance (VLT) | 89% | 64% | 47% | 62% |

| Solar Heat Gain Coefficient (SHGC) | 0.82 | 0.27 | 0.21 | 0.25 |

| STC/OITC* | 32/29 | 34/29 | 40/32 | 27/30 |

| Seal Strength | N/A | 150psi | 150psi | 3000psi |

| Thickness | 6 mm | 25 mm | 44 mm | 8.3 mm |

Above data is for reference only. Calculation method not approved yet by National Fenestration Rating Council (NFRC) for VIG units. Specific product configurations, including substrates and low-e coatings, may affect the performance of constructed glazing systems.

*STC/OITC Tolerance +/-2

VacuMax™ VIG features a cleaner look and

improved sight lines, making for a more attractive unit.

Use VacuMax™ VIG to achieve:

- Extraordinary R-values that deliver energy savings and reduced operational carbon by way of lower Btu usage

- Longer life compared to competitive VIG products as a result of SGCC -certified tempered safety glass and a flexible, strong, non-leaded proprietary metal seal to ensure higher vacuum capability

- Increased acoustic performance for dramatic noise reduction

- Reduced center of glass condensation at temperatures as low as -58° F

- Flatness and strength due to the VacuMax™ VIG low temperature sealing technology

- Generous window-to-wall ratios without sacrificing performance or occupant comfort

VacuMax™ VIG units are available with Solarban® 70 solar control, low-e glass by Vitro Glass, which can help to further enhance the energy efficiency performance of the IGU.

Hybrid VacuMax™ VIG Units

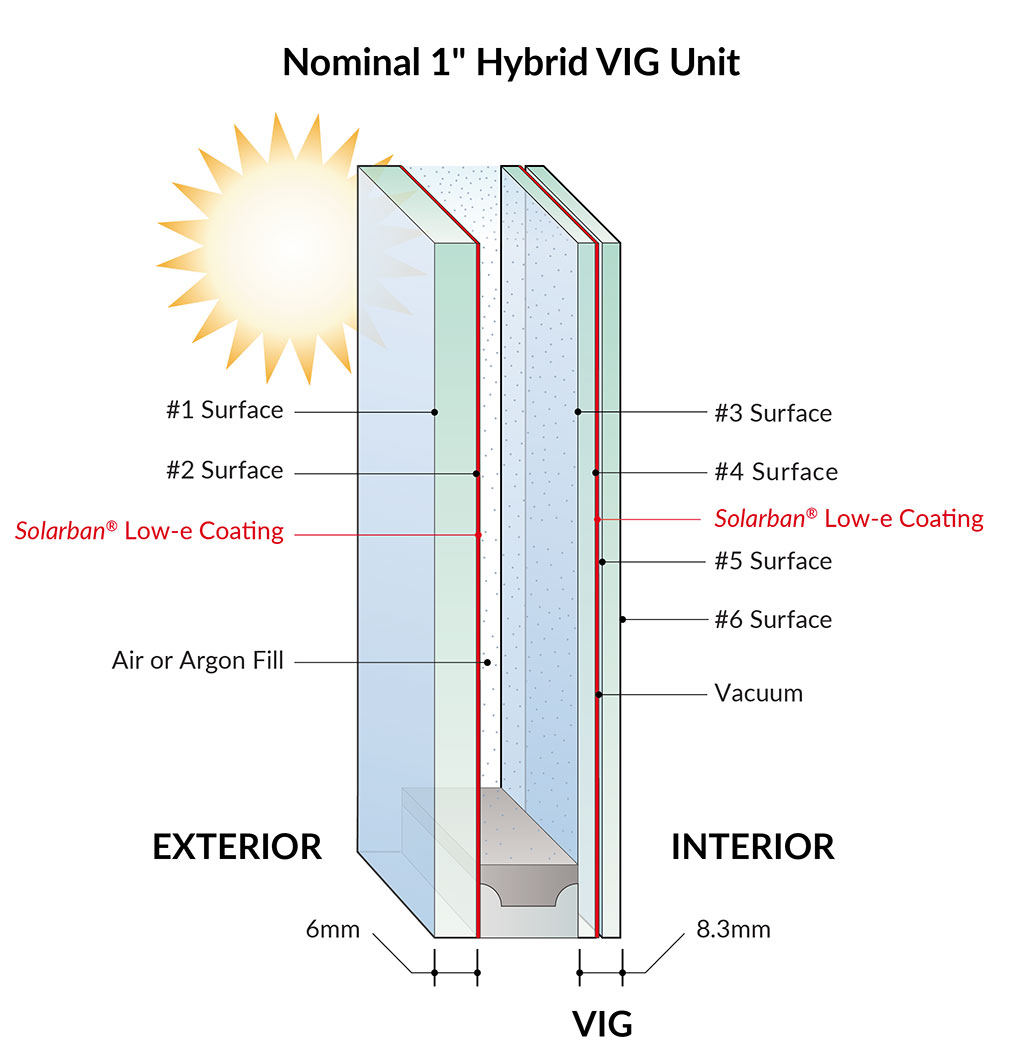

VacuMax™ VIG can also be used as a substitute for the exterior or interior lite in any double- or triple-glazed insulating glass unit (IGU), where it forms a second airspace and creates a hybrid IGU. Multi-pane IGUs utilizing VacuMax™ VIG units still include traditional airspaces adjacent to traditional glass lites.

The simplest and most complex Vitro Glass configurations — from a simple monolithic lite of Starphire Ultra-Clear® glass to a double-glazed IGU with a Solarban® low-e coating on the #2 surface and a bird-friendly pattern on surface #1— can benefit from remarkable performance improvements by replacing the innermost lite with a VacuMax™ VIG unit.

Where to Use VacuMax™ VIG Units

Consider VacuMax™ VIG for exterior glazing applications that require extraordinary insulating performance. VacuMax™ VIG is ideal for residential and commercial projects, including:

- Renovations

- New Construction

- Office buildings

- Educational institutions

- Hospitality

- Healthcare

Awards & Honors Back to Top

- 2x Product Innovation Award, Architectural Products

- Best of Products, The Architect’s Newspaper

- Top 75 Products, Building Design + Construction

- Top Product of the Year, Environment+Energy Leader

Rivaling the thermal performance of traditional walls, VacuMax™ VIG has been recognized for delivering thermal insulation performance three to five times better than conventional insulating glass units and up to 20 times better than monolithic glass.

Fabrication & Availability

Vitro Glass has partnered with LandGlass and VIG Technologies to become the exclusive provider of their high-performance tempered vacuum insulating glass (VIG) products in North America.

Hybrid glass configurations using VacuMax™ VIG units are exclusively available through the Vitro Certified® Network of glass fabricators and window manufacturers. VacuMax™ VIG units are always tempered for safety and to ensure they perform exceptionally across indoor and outdoor temperature extremes.

Extended lead times apply to products using VacuMax™ VIG. Please consult with your National Architectural Manager or Commercial Account Manager for additional technical and logistics information.

Get the VacuMax™ Brochure

Get detailed product information, performance data and more.